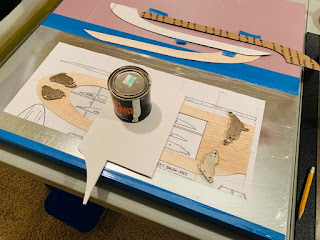

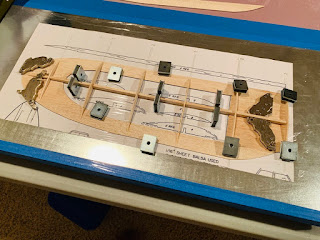

Bottom wing

I decided to modify the build process of the bottom wing. The process is similar to the top wing but in this case I will keep the bottom sheet firmly held flat while gluing on the top sheet. Second, I am going to glue the top sheet in sections: LE, TE, then wing root. I'll be fitting each section into place individually instead of gluing it as one assembled piece. To do this, I cut the TE sheet with a 1/4" extra material at the edge where the TE meets the LE. Once the LE is glued and dry, dry-fit the TE, mark the line where both edges meet, and cut. The edge may need some (very) light sanding with a straight sanding block to get a good fit The two bottom sheets, spar, ribs, and dihedral brace are done. The left wing panel is held down to the building board and has the LE sheet fit and glued. The TE sheet is waiting for its turn. TE sheet now glued. The balsa sheet might need to be damp in order to help in forming it to the rib curvature. The left wing panel is done and perfect...